OKB

Application

- OKB cable is designed for installation into grounds of 1-5 groups (depends on cable construction), cable ducts, tunnels in case of high requirements of crush strength. OKB from flame retardant materials is designed for installation according to exclusive standards of fire safety.

- OKB cable with flame retardant protective jacket is designed for installation according to exclusive standards of fire safety.

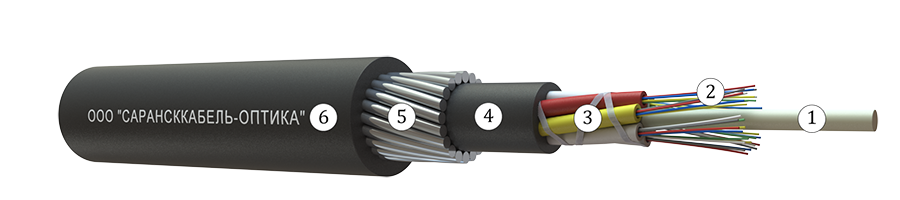

- Central strength member – fiberglass reinforced plastic rod

- Optical fiber

- SZ stranded loose tubes filled with hydrophobic gel

- Inner jacket

- Zink-coated steel wire armor

- Protective jacket

* longitudinal watertightness of the cable is provided by a hydrophobic gel

(8342) 473-813, 480-299

| Number of fibers | |||||

|---|---|---|---|---|---|

| Nominal overall diameter, mm | |||||

| Total mass of cable with polyethylene jacket, kg/km |

* the data correspond to a cable of 7kN

** total mass of the cable with flame retardant protective jacket is specified when ordering

- Yellow tube - main.

- Red tube - guide.

- Natural tubes - counting from the red tube.

- Black fillers are made of polyethylene.

By the customer’s request the color scheme may be changed.

| Temperature range of operation, С° | |

| Temperature range of installation, С° | |

| Minimal bending radius | |

| Lifetime | |

| Guarantee exploitation | |

| Tensile strength | not less than 7 kN for laying in grounds of 4-5 groups; |

| Crush strength | not less than 7 kN for laying in grounds of 4-5 groups; |

** In case of cable with flame retardant protective jacket, the min. installation temperature is not lower than -10 °С.